QUALITY METAL CASTING SINCE 1984

The predecessor of our company started operating in the year 1984, in the city of Abony, HUNGARY. After many successful years, today we operate as an Ltd.

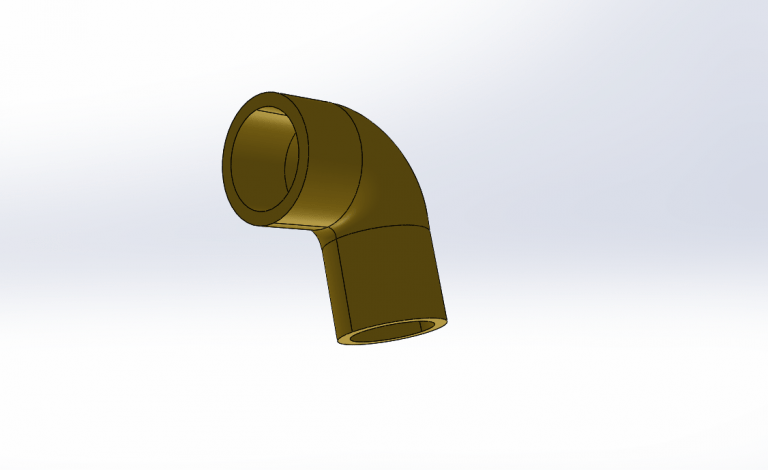

The main profile of AFEM is gravity casting of nonferrous alloys, mainly aluminum, brass and bronze alloys, into permanent and sand moulds. Our large variety of products can be found in the railway, public transportation and machine manufacturing industries.

The company is a thrid generation family owned business.

Technologies

PERMANENT MOULD CASTING

- 200 - 10.000 parts/year, medium to large series

- Short production time

- Good dimensional accuracy

- Aluminum and alubronzes

- Up to 50 kg/part

SAND MOULD CASTING

- 1 - 200 parts/year, prototypes or low serie

- Time consuming production

- Average dimensional accuracy

- Aluminum and tinbronze alloys

- Up to 100 kg/part

HEAT TREATMENT

- Mainly T6 HT of AlSiMg alloys

- Up to HB 100-110

MACHINING

- Turning

- Milling

- Pressing

- Abrasive finishing

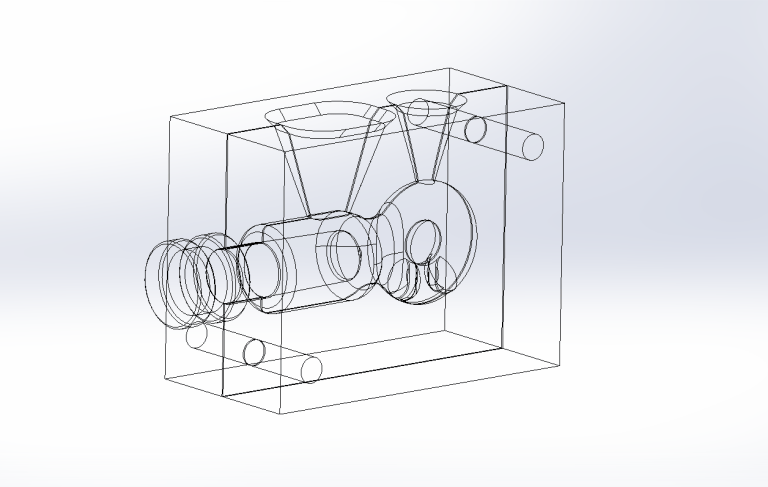

3D PRINTING

- Mainly for sand casting pattern production

- Short production time, highly accurate prints

- PLA/ABS

- Up to 200x300x200 mm

MATERIAL TESTING

- Spectrometry

- X-Ray (soon)

- Hardness testing

Production